Lubricating a retractable awning keeps its joints, arms, and motor running smoothly, preventing squeaks, sagging, and costly mechanical damage while extending its lifespan through every season.

Seasonal Awning Care That Prevents Damage, Saves Repairs, and Keeps Things Moving

Proper maintenance keeps your awning running for decades.

Without it, weather and wear lead to stuck joints, strained motors, and failing smart features, but seasonal care is quick and easy. Quick maintenance essentials:

- Lubricate twice yearly – Once in spring, once in fall.

- Use dry silicone spray – It’s clean, fabric-safe, and non-staining.

- Clean before lubricating – Prevents grime from being trapped inside joints.

- Target high-friction points – Roller tube axle, elbow joints, brackets, and pitch crank.

- Avoid over-spraying – Excess lubricant attracts dust and accelerates wear.

- Protect surroundings – Mask off siding, sensors, and fabric to avoid damage.

- Watch for warning signs – Creaks, slow movement, or uneven retraction mean it’s time for attention.

A few minutes twice a year prevents the bigger problems, like drooping arms or motor overload, that can impact an awning’s life.

Knowing the right tools and technique now will save repairs later, so let’s break down exactly how to keep yours running like new.

Why Smart Awning Owners Are Prioritizing Regular Maintenance

Modern retractable awnings do more than provide shade, they’re part of how people live outdoors.

But like anything exposed to the elements, they need regular care to keep joints, motors, and fabric working properly.

What Happens When You Skip Maintenance

Letting seasonal upkeep slide might seem harmless at first, but over time it chips away at your awning’s performance and lifespan. Here’s what tends to happen:

- Joints dry out and seize up. Without lubrication, elbow joints and torque arms stiffen. Movement becomes jerky, noisy, or stops altogether.

- Motors work harder than they should. Increased resistance from dry joints makes motorized systems strain unnecessarily. This can trigger thermal shutdowns or shorten motor life.

- Smart features stop being smart. Wind sensors and auto-retract systems rely on smooth hardware to respond correctly. If parts are dry or stuck, even your smart awning can misfire.

- Cosmetic issues turn into functional failures. Fading fabric or crooked pitch might look minor, but they often signal deeper stress in the frame.

Skipping maintenance affects more than looks, it impacts how safely and smoothly your awning operates. Creaks, slow movement, or uneven retraction are early warning signs it needs attention.

Helpful Resource → How Long Do Awnings Last? Lifespan by Type & Care Tips

Why Proper Installation Sets the Tone

A good awning install doesn’t just mount the awning, it protects it. Professional crews lubricate all key joints, align brackets for even weight distribution, and prep the unit based on your climate.

That early attention to detail makes seasonal upkeep faster and more effective later on.

Consistent upkeep lays the groundwork for smooth, reliable operation, but lubrication is the step that truly keeps everything moving.

Knowing the right tools, timing, and technique makes all the difference in protecting your awning’s performance.

How to Lubricate a Retractable Awning Without Ruining It

Even the best awnings need a little help to keep moving smoothly.

The right lubrication method prevents wear, protects sensitive parts, and ensures every extension or retraction feels effortless. Follow these steps to get it right the first time.

1. Tools and Materials You’ll Need

- Dry silicone spray (fabric-safe, non-staining)

- Soft cloths or paper towels

- Mild soap and water

- Ladder with stabilizers (if needed)

- Safety glasses and gloves

2. Prep Before You Spray

Lubricate twice a year, once in spring and once in fall.

Clean all pivot points using mild soap and water to remove dirt and buildup. Let everything dry fully before spraying.

Skipping this step traps debris in the joints, reducing lubricant effectiveness, especially in dusty or coastal areas.

3. Where to Apply Lubricant

Target high-friction zones: the roller tube axle, elbow joints, brackets, and pitch crank.

Spray directly into pivot points, not just the outer metal. For awnings with pitch adjustment or automation, also treat hidden hinges, they often go overlooked.

4. Avoid Over-Lubrication

Use short bursts, enough to coat the joint, not soak it. Too much spray attracts dust and can accelerate wear instead of reducing it.

5. Protect Surrounding Surfaces

Hold a cloth behind joints while spraying to prevent drips. Fabric-safe doesn’t mean risk-free, overspray on siding, fabric, or sensors can still cause issues.

Mask off nearby surfaces when needed.

Lubrication keeps your awning moving smoothly, but it’s only part of the picture.

To maintain it at its best, you also need to understand why joints fail in the first place, because preventing the cause is always easier than fixing the damage.

If you’d rather leave it to the pros, Marygrove’s Mint Program offers professional awning maintenance that includes expert lubrication of all moving parts, frame inspection, sensor testing, and more.

So your awning stays smooth, quiet, and season-ready without any guesswork.

What Causes Awning Joints to Fail And Why Lubrication Is the Fix

Retractable awnings can handle daily use, but the real threat isn’t movement, it’s the environment. Weather, friction, and skipped maintenance quietly wear down joints until they stick, squeak, or seize.

1. Weather Is Hard on Metal

Awnings face humidity, UV rays, rain, and temperature swings year-round. Humid climates speed up corrosion, while cold weather can thicken or break down lubricants.

Even light wind adds constant vibration that stresses pivots and brackets if they’re unprotected.

2. Where the Wear Happens

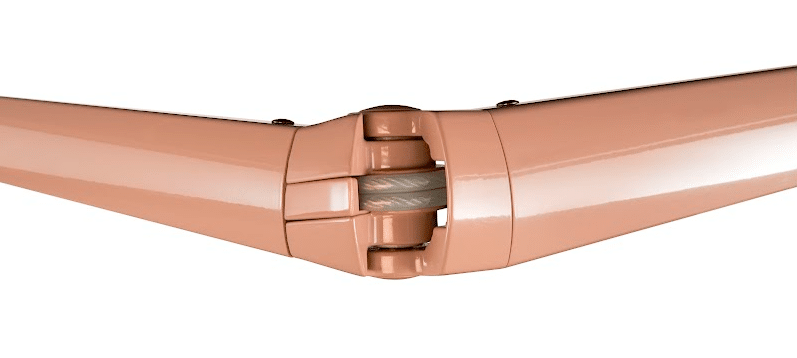

High-torque pivot points, like elbow joints, torque arms, and roller bushings, bear the most strain.

When dry, they create friction that slows movement, makes arms creak, and forces motors to work harder.

Self-lubricating joints help but aren’t maintenance-free; dust, grime, and seasonal shifts still reduce performance.

Example of an awning arm

3. Noises Can Be Misleading

Squeaks are often blamed on motor failure, but most noises come from dry joints.

Even unused awnings can stiffen over time, making seasonal lubrication essential whether you use it daily or rarely.

4. The Spots People Forget

DIY maintenance often skips smaller pivot points hidden inside elbow arms or pitch mechanisms. Neglecting these friction zones shortens lifespan more than most owners realize.

Lubrication isn’t just a tune-up, it’s protection for the parts you can’t see but rely on every time you open or close your awning.

Knowing where and why joints fail is only half the battle, the way you maintain them matters just as much. Avoiding common lubrication mistakes will protect both your awning’s performance and its warranty.

Check out More On Awning Maintenance Here: Everything About Awning Maintenance

Mistakes That Can Void Warranties or Cause Damage

- Using the wrong product: Avoid WD-40, grease-based sprays, or anything petroleum-based. These attract dirt, break down under heat, and may void manufacturer warranties.

- Spraying near smart sensors or wiring: Overspray can interfere with sensor response or cause corrosion if it gets into the wrong place.

- Skipping cleaning before lubrication: Trapping grime inside joints reduces movement and causes wear. Always clean first. Best if you schedule awning cleaning with lubrication.

- Spraying with the awning retracted: It limits access and forces you to guess where joints are. Fully extend the awning for safe, accurate application.

- Working from unstable ladders or without support: Safety first, always secure your ladder and avoid leaning into extended awnings while applying pressure.

Lubrication isn’t about doing more, it’s about doing it precisely. A little care, the right product, and clean joints will go a long way in keeping your awning smooth and quiet.

What Happens If You Don’t Lubricate? (And How to Spot the Damage Early)

Skipping lubrication doesn’t cause instant failure, but it starts a slow breakdown in the parts you rely on the most. Here’s what tends to go wrong when joints are left dry and unprotected:

- Creaks Become Cracks: Dry elbow joints start to creak, but continued use wears down the metal and can lead to permanent fractures.

- Roller Drag and “Ghost Noises”: Hesitation or jerky motion often comes from dry rollers, not a faulty motor, creating unsettling sounds as resistance builds.

- Motor Overload Trips: When joints seize up, the motor works harder than it should, often triggering thermal shutoff protections or shortening its lifespan.

- Smart Sensors Stop Responding: Wind sensors and auto-retract features rely on free movement, when joints bind, smart automation fails or misfires.

- “Is My Awning Dying?”: Noisy operation is usually a call for maintenance, not replacement, but skip too many seasons and damage can become irreversible.

While most of these issues can be prevented with timely lubrication, some warning signs point to deeper problems that maintenance alone can’t solve.

When Lubrication Isn’t Enough

If joints still grind, arms pop, or the awning resists movement after proper spraying, it likely means there’s internal mechanical wear.

This could be a bent bracket, worn bushing, or misaligned pivot that lubrication alone can’t fix. At that point, continuing use can worsen the damage and risk more expensive repairs.

Most lubrication issues are simple to fix, but the longer they’re left unaddressed, the harder they are to reverse.

Staying ahead of these signs is the easiest way to protect your awning from preventable damage.

Keeping Your Awning at Its Best

A retractable awning is more than shade, it’s an investment in comfort, curb appeal, and usability.

Protecting that investment means understanding how it works, recognizing the early signs of wear, and following a simple maintenance routine that includes proper lubrication.

By staying ahead of environmental damage and avoiding common mistakes, you ensure your awning operates smoothly season after season, with fewer costly repairs and a longer lifespan.

When it comes to reliability, Marygrove truly stands out: our awning motors have less than a 1 % failure rate over five years, giving you consistent performance without the worry.

Ready for low-maintenance reliability and flawless performance?

Reach out to Marygrove Awnings today to explore our top-tier, durable motorized retractable awnings designed for lasting outdoor comfort.